OP Jindal university (OPJU) has established a Centre of Excellence in Manufacturing and Automation (CoEMA) which comprises Welding Technology and Inspection, Advanced Machining, Rapid Prototyping, Digital Manufacturing, Automation Technology and Metrology & Quality Control. This Manufacturing and Automation Centre will be utilized for industrial output so that the trainees learn on actual jobs and work for future up gradation of technology. The primary objective of the Centre is to bridge the technological gap between industry requirement and academic curriculum. The Centre will focus on Training, Consultancy and Research programs which will help in catering to the growing demand from Engineering and Manufacturing Industries in India. This Centre will also enable training to the personnel of industry in the central region in cooperation with our esteemed partners. The Centre will also help the stakeholders for taking up entrepreneurs’ field, guest lectures, curriculum development, internships to students, and joint collaborative work.

To provide skill excellence through Training, R&D and Consultancy for robust Industry relevant technical education eco-system.

To offer certified skill development programs for enhancing placement opportunities.

To promote industry-academia partnership by engaging in extensive consultancy services.

To engage in Research and Development for societal benefit.

To strategically align with Institute’s Vision and Mission for building the brand image.

Virtual Welding Simulator

Simulation of Welding Process using ANSYS

CNC Lathe

CNC Wire Cut EDM

Material Testing (UTM, Impact, Fatigue, Hardness)

Shielded Metal Arc Welding (SMAW)

Gas Metal Arc Welding (GMAW)

Gas Tungsten Arc Welding (GTAW)

Gas Welding / Brazing / Cutting

Non-destructive testing

Robotic Welding

The Department of Mechanical Engineering, School of Engineering, OP Jindal University Raigarh, organised a one-day immersive CNC machining session for the students of the 5th semester on 09th August 2024, in collaboration with the Centre of Excellence in Manufacturing and Automation and the SAE India Collegiate Club of OPJU. The students engaged in a comprehensive training program, delving into Computer Numerical Control (CNC) technology.Through interactive learning, participants acquired fundamental knowledge in: CNC coding, Machine operation and safety, Toolpath simulation, and Actual production processes.

On 13th June 2024, Mr CN Singh, ED & HOP of JPL Tamnar, along with his team members, visited the Centre of Excellence in Manufacturing & Automation (CoEMA) under the Department of Mechanical Engineering at OPJU. During the visit, Mr. Singh and his team toured the facility, interacted with faculty members, and observed various ongoing projects and initiatives. He expressed his appreciation for the state-of-the-art equipment and innovative approaches being implemented at CoEMA.

The Centre of Excellence in Manufacturing and Automation (CoEMA), under the Department of Mechanical Engineering was inaugurated on 15th March 2024 during the Industry-Academia Conclave held on March 15-16, 2024, at OP Jindal University Raigarh. The event was graced by renowned industry leaders from different sectors of the industry. Through strategic collaborations and interdisciplinary approaches, the centre aims to address the evolving needs of the manufacturing sector and contribute to India's vision of becoming a global manufacturing powerhouse.

Three teams of talented female B.Tech students from the School of Engineering, OPJU, showcased their skills at the National Welding League of Women Engineering Students (NWL2024). They underwent rigorous training at the Centre of Excellence in Manufacturing and Automation (CoEMA) under the Department of Mechanical Engineering.

The Department of Mechanical Engineering, in collaboration with the Centre of Excellence in Manufacturing & Automation at the School of Engineering, OP Jindal University, conducted a one-week training program on "CNC Machines" from January 8th to 12th, 2024, for ITI students. The program aimed to enhance the skills of students from nearby ITI colleges. This phased training benefited participants by expanding their understanding of conventional machining and exposing them to the latest advancements in machining technologies, including NC, CNC, metrology and along with industry visit.

The Department of Mechanical Engineering, in association with the Centre of Excellence in Manufacturing and Automation (CoEMA) at OPJU, has conducted a” five-day CNC training program from 4th to 8th December 2023. The participants were from Govt. ITI, Raigarh. The program was designed to equip students with practical knowledge and hands-on experience in Computer Numerical Control (CNC) operations, fostering their understanding of modern manufacturing techniques. During the inauguration of the training program, Dr Siddharth S. Chakrabarti, Dean SoE and HoD-Mechanical Engineering, welcomed the participants and asked the participants to take part enthusiastically in this program. Throughout the program, participants delved into the intricacies of CNC machining, learning from subject experts and engaging in practical sessions that honed their skills in programming, tooling, and operating CNC machines. Moreover, the highlight of this program was the opportunity for our students to explore cutting-edge technologies at OPJU innovation center, witnessing firsthand the innovation and capabilities in manufacturing and prototyping. The exposure to Wire Cut EDM, 3D printing, and Laser engraving was both enlightening and inspiring, showcasing the incredible advancements shaping the future of manufacturing. At the end of the training program, Dr. Umesh Vishwakarma, Associate Professor, Mechanical Engineering, thanked all the guests, students and faculty members for their cooperation and active participation in the programme.

1. Vritika Research Internship program on “Advanced Welding and Inspection Technology”, successfully organized by the Department of Mechanical Engineering in collaboration with the Centre of Excellence in Manufacturing and Automation (CoEMA), OP Jindal University Raigarh. This one-month program ((1st – 31st Aug 2023), aims to provide young scholars with hands-on research skill development experience and inspire them to pursue research-oriented careers. Students honed their welding skills during the program using virtual and real equipment. They also engaged in non-destructive testing, robotic welding and attended expert lectures on manufacturing advancements. Industry visits exposed them to real-life operations, while a visit to the Institute Innovation Cell showcased cutting-edge technologies. The program is sponsored by the Science & Engineering Research Board (SERB), Department of Science and Technology (DST), Govt of India, under the Accelerate Vigyan scheme. Also, we are very grateful for the continuous guidance and support provided by the Hon’ble Vice Chancellor throughout the program.

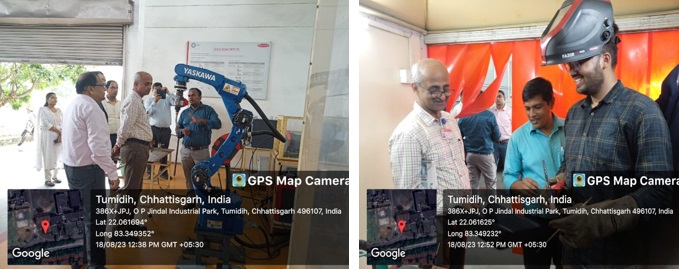

2. Senior officials from NTPC, Lara, visited the Centers of Excellence and the academic facilities of the University on 18th August 2023. The visit was a unique opportunity to bridge the gap between academia and real-world applications.

3. Senior officials from Tata Hitachi, Kharagpur, visited the Centers of Excellence and the academic facilities of the University on 5th September 2023. The visit was a significant event aimed at fostering collaboration, sharing knowledge, and strengthening the industry-academic partnership. The visit served as an opportunity for industry leaders to witness the commitment of OPJU to producing competent, job-ready engineers.

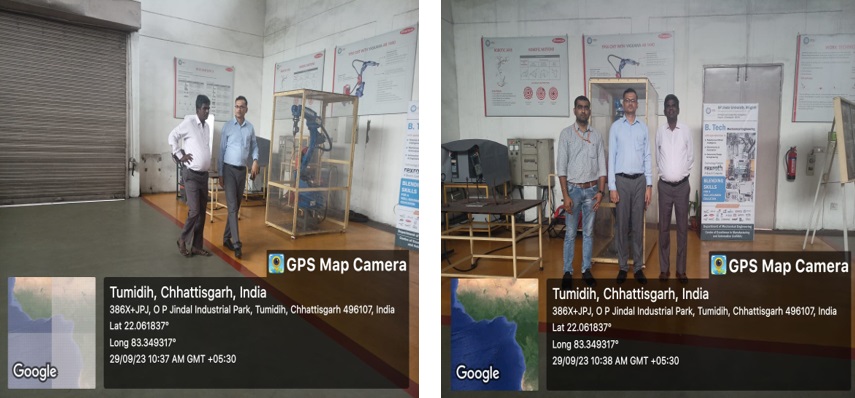

4. Prof. S. Murgan, Professor at the Department of Mechanical Engineering National Institute of Technology, Rourkela, visited the Center of Excellence in Manufacturing and Automation at OP Jindal University, Raigarh, on 29/09/2023. The visit served as an opportunity to showcase our work and seek valuable feedback.

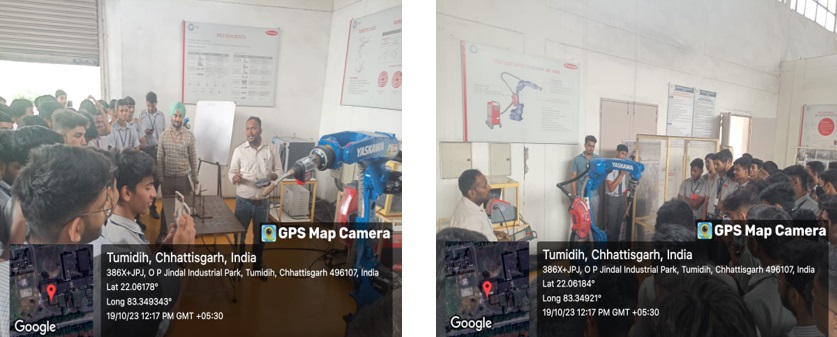

5. The students of OP Jindal School, Raigarh, visited the Centre of Excellence in Manufacturing and Automation at OP Jindal University, Raigarh, on 19 October 2023. The students explored the advanced welding technology and CNC machine during the session. It has provided a unique opportunity to inspire the next generation of engineers and innovators. By offering an engaging, hands-on, and educational experience that showcases the breadth and depth of engineering, we can ignite their passion for the field, foster scientific thinking, and potentially influence their academic and career choices.

6. A new CNC lathe machine was installed in the Centre of Excellence in Manufacturing and Automation at OP Jindal University, Raigarh 09/10/2023. CNC machines are instrumental in modern manufacturing and various industries due to their precision, efficiency, and versatility. They offer significant advantages in productivity, cost savings, and quality control, making them a cornerstone of advanced manufacturing processes. It can be used for research, consultancy and training purposes.

7. The Department of Mechanical Engineering, in Association with the Center of Excellence in Manufacturing & Automation, organized a one-day training program on “CNC Lathe Machines” on 26 October 2023 for final year B Tech students. The training program was organized to upgrade the skills and provide exposure to the latest advancements in machining technologies.

1. The Department of Mechanical Engineering, OP Jindal University in association with the Centre of Excellence in Welding Technology (CoEWT), Yaskawa India Pvt. Ltd. and Fronius India Pvt. Ltd. jointly organized a Training Programme on "Robotic Welding Technology" from 5th to 8th April 2022 at OPJU Campus. The training program enabled the participant to program robotic welding set up to perform various welding operations. The robotic welding setup can further be utilized for Research. The participants were faculty, students and personnel from nearby industries and other esteemed organisations.

2. Department of Mechanical Engineering, in association with IIC OPJU, organized a five- day training Program on " ANSYS-Hands on Workshop" from 4th to 10th May 2022. The students got an exposure to the new technology and capabilities of the software that can be utilized to support their innovations in Engineering and perform the simulations. Dr. R.D. Patidar, Honourable Vice-Chancellor, OPJU distributed the certificates to students and also motivated the students with his kind words.

3. Department of Mechanical Engineering, in association with the Centre of Excellence in Manufacturing and Automation conducted a value-added training on “Metal Joining Technology: Simulator Hands-On Session” from 16th May 2022 to 20th May 2022. The course was attended by B.Tech first year students. This course provided the trainees with the necessary knowledge & skills required by B. Tech graduates to become competent welding engineers as per the need of the manufacturing and fabrication industries. It was an introductory course and 20 students attended the course. The course mainly included the basic introduction to metal joining technology, evaluation and selection of welding processes and rigorous practice on virtual welding simulator.

4. Department of Mechanical Engineering in association with Centre of Excellence in Manufacturing and Automation (CoEMA) organised a full-time one-month Industrial Internship Program (Certificate Course) from 6th June 2022 to 5th July 2022. The internship was mainly focused on imparting practical knowledge of welding technology to the students by adopting the learning-by-doing approach and was attended by participants from various esteemed institutes of Chhattisgarh. The internship included theory classes covering the basic to advanced welding technologies, sessions on weld quality, underwater welding, actuation technologies, robotic welding, programming and hands-on sessions in virtual welding simulators covering MAG, MMAW, and TIG in various positions of the workpiece.The participants also got the opportunity to work on CNC routers, Laser engravers, 3D printers of the OPJU innovation centre. The internship also included industrial visits to JPL, Tamnar, Nalwa Steel & power Ltd., and SSD Punjipathra.

5. Weld talk series: Department of Mechanical Engineering in association with Centre of Excellence in Manufacturing and Automation (CoEMA) organised a series of lectures on Advanced Technology in the month of June 2022. The session was fruitful for the students of 6th and 4th semester along with the students undergoing industrial internship.

| S.No | Date | Speaker | Topic | Industry | Photograph |

|---|---|---|---|---|---|

| WeldTalks1 | 9th June2022 | Mr.C. Raghvan | Robotic ArcWelding | Fronius IndiaPvt. Ltd | |

| WeldTalks2 | 13th June2022 | MrSudipto Banerjee andMr Sudhir Kumar Lall | Repair & Maintenance Welding in Steel Industry | WearresistTechnology Pvt Ltd | |

| WeldTalks3 | 13th June2022 | Mr KamleshSingh | New developments in Plasma CuttingTechnology | Ador WeldingLtd | |

| WeldTalks4 | 14th June2022 | Mr Nimesh SChinoy | Advancesin TIG Welding from Semi-Automaticto Fully AutomaticMachines | ElectronicDevices Worldwide PvtLtd | |

| WeldTalks5 | 14th June2022 | Mr N Sridhar | New Trends inMaintenanceand RepairWelding. | Ador FontechLtd | |

| WeldTalks6 | 23rd June2022 | Mr.RiturajBose | Occupational Health andSafety inWelding | TheIndian Instituteof Welding | |

| WeldTalks7 | 28th June2022 | Mr. DhaneshNarayanan | Trends inIndustrial robotics | YaskawaIndia | |

| WeldTalks8 | 29th June2022 | Mr. DhaneshNarayanan | Application ofindustrial robots | YaskawaIndia |

6. The students of Diploma 3rd Semester of the Department of Mechanical Engineering are undergoing a hands-on session on “Advanced Welding Technology” at Centre of Excellence in Manufacturing and Automation from 19th September 2022 to 28th October 2022. During the session the students will explore the advanced welding technology and will do the practical jobs on SMAW, GMAW and GTAW technology. This training will enhance their technical knowledge and skills in the related area.

7. Welding is an essential component of many industries such as the automotive industry, the construction industry, the aviation industry, and many more. To enhance the welding skills of students, Department of Mechanical Engineering in association with the Center of Excellence in Manufacturing and Automation organised a 6 weeks value added course on “Welding Technology” for Diploma 3rd semester students. The course was conducted during 19th September 2022 – 28th October 2022. Dr. Umesh Vishwakarma, Mr. Prashant Padhi, and Mr. Narendra Deshmukh conducted the course.

8. The Department of Mechanical Engineering in association with the Centre of Excellence in Manufacturing and Automation (CoEMA) proudly announces its participation in the National Skill Competition for Best of the Best Welders 2022 (An Associate Event of the International Institute of Welding) to be held at CV Raman Global University Odisha. Our three students from Diploma in Mechanical Engineering have been selected for competition under various categories. The event has more than 45 registered participants from various parts of the country and we are the only participants from the State of Chhattisgarh

9. The Department of Mechanical Engineering in Association with the Center of Excellence in Manufacturing & Automation organized a five-days training program on “CNC Machines” during 05th – 09th December 2022 for ITI students. The training program was organised with an aim to upgrade the skills of students of nearby ITI colleges. This phase- wise training benefited participants in the area of conventional machining and provided an exposure of the latest advancements in the machining technologies like NC, CNC, and Metrology.

10. OPJU team "Vikrant" comprising of the students of the Department Mechanical and Electrical Engineering, has successfully cleared the first Pre-Virtual Round (Rulebook Test) of SIEP E-Bike Challenge 2023. The event is organized at the national level by the Imperial Society of Innovative Engineers (ISIE INDIA - India's Biggest EV Skill & Research Platform) and Hero Electric.

11. The Department of Mechanical Engineering at OPJU believes in experiential learning and hence continuously provides opportunities to its students to showcase their talent in the National arena. Moving in the same line, this year also the student team "VIDYUT" as a part of the SAE Collegiate Club designed and fabricated their "Formula One Car" under the guidance of Faculties & Staff of Department of Mechanical Engineering and Centre of Excellence in manufacturing & Automation. They participated in the SAE-SUPRA Formula contest, organised between 22nd - 25th August 2022 at Buddh International Circuit, Greater Noida. OPJU was the only University from Chhattisgarh to participate in this event.

12. The Centre of Excellence in Manufacturing and Automation (CoEMA), in association with the Department of Mechanical Engineering have successfully organized a five-days CNC training program during 20 - 24th February 2023, for the final year Diploma Students of Kirodimal Government Polytechnic Institute, Raigarh. The students had hands-on training session in CNC Milling, CNC Lathe CNC engraving, CNC laser cutting and 3D printing. The students also learned about Robotic Welding technology available at OPJU. The training program was concluded by a valedictory session followed by certificate distribution. The centre is focused to conduct skills development programs for the students of Chhattisgarh and central India.

13. OP Jindal University student's team "VIDYUT" under the aegis of SAE India Collegiate Club is working extensively on their Formula One car project “VAYU”. The team has completed the designing and fabrication part of Chassis. The team members are really excited to participate in the formula contest SAE-SUPRA which is scheduled to be held during July 2022 at Buddh International Circuit, Greater Noida. Last year, OPJU was the only University from Chhattisgarh to participate in this event.

14. The Department of Mechanical Engineering organized a Five days training program (17th – 21st March 2023) for the Faculty and Staff on “CNC Wire Cut EDM”. The Five axis fully automatic CNC Wire Cut EDM machine is the latest addition in the Centre of Excellence in Manufacturing and Automation under Department of Mechanical Engineering. It enables us to cut any electrically conductive material irrespective of its hardness with high accuracy and precision. The facility can be utilized for teaching, training, research, and industrial consultancy.

CoEWT at OP Jindal University conducted a one week (4th to 8th Oct, 2021)-training Program on “Metal Joining Technology” for the final year diploma holders to develop basic skills in Welding processes. The training includes, Introduction to Welding Processes, Evaluation and selection of welding processes, Use Safety Equipment’s in welding, Practice on Virtual welding Machines, discussion on power source and consumables.

“In my view, the robust industry-university collaboration will have a multi-fold impact on reducing unemployment, social upliftment, and the nation’s progress by ushering in skill development, innovation, and entrepreneurship”, says Dr. R D Patidar, Vice-Chancellor, OP Jindal University.

As the University is surrounded by several steel industries including our parent organization Jindal Steel & Power Limited (JSPL), a Centre for Sustainable Technology and Product Development (CSTPD) has been established at the campus, to impart our students all the skills which can cater to the needs of the steel industry.

Fronius India has organized “Academicians Conclave 2020” and on 25th June, 2020. For this conclave stalwarts like Dr. R K Agarwal, Director General, Ajay Kumar Garg Engineering College, Ghaziabad; Mr. Sanjib Kumar Rout, Founder President, CV Raman Global University, Bhubaneshwar; Dr. R.D. Patidar, Vice-Chancellor, O.P. Jindal University, Raigarh, Chhattisgarh; Dr. Niranjan Chiplunkar, Principal, NMAM Institute of Technology, NITTE, Karnataka and Dr. Murugaiyan Amirthalingam, Head Joining and Additive Manufacturing, Indian Institute of Technology Chennai were the Panellists. The moderator for this meeting was Mr. V V Kamath, Managing Director, Fronius India Private Limited.

This “Academicians Conclave 2020” focused mainly on the current measures taken by the institutes and the way students’ community is evolving with the time and responding to the current measures of learning. This conclave also helped the attendees to understand how the education sector is gearing up for the change. There were a total of 550 + participants who attended the program.

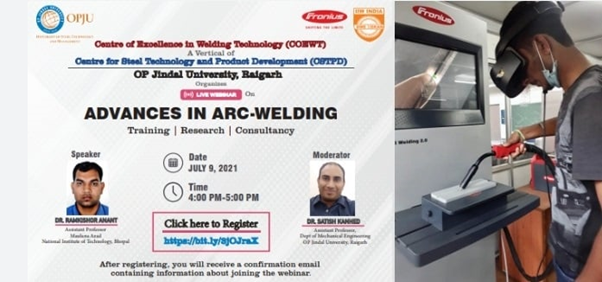

OP Jindal University in association with centre of Excellence in Welding Technology (A vertical of Centre for Sustainable Technology & Product Development) has organised an interactive webinar titled as "Advances in Arc Welding" on 9th July at 4 PM .

Five-Day Online Faculty Development Programme (FDP) on “Mechatronics, Automation and Robotics” in association with IEEE Bombay Section, Centre of Excellence in Welding Technology and All India Council for Robotics and Automation (AICRA) from August 3-7, 2020.

It was a really a wonderful experience for us to host selected 792 participants and every day 400+ participants in zoom with esteemed speakers sharing their knowledge and expertise in different topics related to Advanced manufacturing.

OPJU participated in prestigious 'Electric Solar Vehicle Championship' EVSC-2019 Season 6.0 & 7.0- Asia’s biggest solar event aimed at making a new generation Solar Electric Vehicle. The championship was started in year 2013, with an aim to create awareness among future engineers about renewable energy, resources and its uses. OPJU students fabricated the vehicles using advanced welding techniques and won the “Hero Electric Spirit Awar” at ESVC 2019

Centre team visited the world-class facility of Fronius India Private Ltd, Pune - the partner for Center for Excellence in Welding at OP Jindal University, Raigarh.

Centre member visited Mumbai (6th to 8th Feb, 2020) attending 5th International Congress (IC 2020), Weld 2020 and exhibition. The event was attended by around 500+ delegates and having maximum from industries with around 40+ industries showcase their products in the Weld 2020 exhibition.

The Center of Excellence (COE) in Welding Technology under the Centre for Sustainable Technology and Product Development (CSTPD), OP Jindal University, Raigarh signed a Memorandum of Understanding (MoU) with The Indian Institute of Welding (IIW) Kolkata on 5th Feb, 2020. The partnership has been made for promoting and strengthening academic excellence in various areas of welding science education and certified training by mutual exchange of information and technological development, putting joint efforts in conducting technical sessions, workshops, industry-oriented training programs, seminars and conferences, training and certification schemes, welding research & development activities and disseminating technical information.

The Centre of Excellence in Welding Technology (COEWT), a vertical of the Centre for Steel Technology and Product Development (#CSTPD), #OPJindalUniversity has signed an MoU with Association of Welding Products Manufacturers (AWPM) today. The MoU will help the OPJU and Mechanical students in terms of their Training, Placement, Paid and Unpaid Long Term Internships , and Industry Expert Lectures.

A) Discussions with National Skill Development Council(NSDC)

Welding is an integral part of the steel industry, so it becomes an important vertical of the Centre for Sustainable Technology & Product Development. So, a MoU has been signed with Fronius India Private Limited (FIPL) to establish a centre of Excellence in Welding Technology (CoEWT) at MoU signing ceremony of INDIA STEEL 2019. The ceremony was held under the Chairmanship of Secretary, Ministry of Steel, Government of India along with other dignitaries from the Ministry and Industry (https://www.indiasteelexpo.in/pdf/2019/PostShow2019.pdf).

A white paper on “Weld 4.0 : Intelligentized #Welding in India” prepared by OP Jindal University has been released by Confederation of Indian Industries (#CII) at the 2nd conference on #WeldingTechnology-2017 held on 29th November at #Mumbai . (https://www.cii.in/ResourceDetails.aspx?enc=g/PQTg848IxIfTFD0dEKpUxvX5O3CBTvzCnmW6El5dJ4/T1iLwogEwKFSfkS2fkwXxW7u7qJjIbemMtFS78m4A==) White Paper: https://www.mycii.in/KmResourceApplication/58283.WhitePaperWeld40.pdf

The Centre of Excellence in Welding Technology (CoEWT) at OPJU in association with the Department of Mechanical Engineering, HRD Centre and Academic Staff College (ASC), OPJU, and Fronius India Private Limited, Pune have jointly organized a Training Programme (Certificate Course) on “Advanced Welding Technology” from 6th to 10th December 2021. The training covered various topics namely– Introduction to advanced welding, Inverter technology, MIG, TIG, and MMAW Practice on virtual welding simulators & physical welding machines and introduction to welding defects. The training was attended by industry persons from esteemed organizations such as Jindal Power Limited, Steel structural division, OP Jindal Community College, JSW, and others.

Dr. Suryakumar. S

Dr. Suryakumar. S

Professor, Department of Mechanical & Aerospace Engineering

IIT ,

Hyderabad

Dr Prince Singh

Dr Prince Singh

Assistan Professor

IIT

Ropar

Dr C K Biswas

Dr C K Biswas

Professor

NIT,

Rourkela

Dr. Ramkishor Anant,

Dr. Ramkishor Anant,

Assistant Professor,

MANIT ,

Bhopal

Dr. Santanu Das

Dr. Santanu Das

Chairman,

Welding Education Committee and Chief Editor,

Indian Welding Journal

Mr. Vishal Chakral,

Mr. Vishal Chakral,

Mahindra & Mahindra Pvt. Ltd.

Dr. Krishnan Sivaraman

Dr. Krishnan Sivaraman

Sr. DGM

Welding and Quality,

L & T Limited, Mumbai

Dr. R. Selvaraj

Dr. R. Selvaraj

Chairman,CSI

Tiruchirappalli Chapter, BHEL

Tiruchirappalli

Dr Siddharth S Chakrabarti

Dr Siddharth S Chakrabarti

Professor & Head

Mechanical Engineering Department,

OPJU

Dr Umesh Kumar Vishwakarma

Dr Umesh Kumar Vishwakarma

Associate Professor

Mechanical Engineering Department,

OPJU

Prof Jitesh Singh

Prof Jitesh Singh

Assistant Professor

Mechanical Engineering Department,

OPJU

Dr Mahesh Bhiwapurkar

Dr Mahesh Bhiwapurkar

Professor

Mechanical Engineering Department,

OPJU

Dr Mukesh Desai

Dr Mukesh Desai

Associate Professor

Mechanical Engineering Department,

OPJU

Prof Neeraj Verma,

Prof Neeraj Verma,

Assistant Professor

Metallurgical Engineering Department,

OPJU

Dr Satish Kanhed

Dr Satish Kanhed

Assistant Professor

Mechanical Engineering Department

OPJU

Prof. Ravindra Singh Saluja

Prof. Ravindra Singh Saluja

Associate Professor

Mechanical Engineering Department

OPJU

| S.No. | |||

|---|---|---|---|

| 1 | Manufacturing and Automation | Dr Siddharth S Chakrabarti Dr Umesh Kumar Vishwakarma Prof Jitesh Singh Dr Satish Kanhed Dr Mahesh Bhiwapurkar Dr Mukesh Desai Prof. Neeraj Verma | Dr. R. Selvaraj, BHEl, Tiruchirapalli Dr. Krishnan Sivaraman, Sr. DGM, Welding and Quality, L & T Limited, Mumbai Mr. Vishal Chakral, M&M Pvt. Ltd. Dr. Ramkishor Anant, MANIT Bhopal Dr C K Biswas, Professor, NIT Rourkela Dr Prince Singh, Professor, IIT Mandi Dr. Santanu Das, Chairman, Welding Education Committee and Chief Editor, Indian Welding Journal |