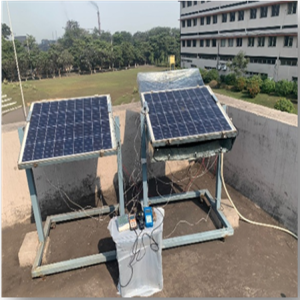

The Central Workshop features advanced experimental and machining setups designed to provide students with hands-on experience in the principles and applications of machining systems and constructing two-and four-wheeler electric vehicles. Modern equipment and machines including, CNC Lathe, Capstan Lathe, Centre Lathe, Shaper Machine, Universal Milling Machine, Planer Machine, Slotting Machine, Radial Drilling, MIG/MAG Welding, Spot Welding, Gas Welding, MMA Welding, Open Hearth, Muffle Furnace, Circular Saw Machine, Woodworking Lathe, etc., enables students to have On-The-Job training on the machines. The Central Workshop is well-furnished to support undergraduate (Diploma, B. Tech) and postgraduate (M. Tech) student projects. Central Workshop includes Machine...

.jpg)

.jpg)

.jpg)

-(1).webp)

.jpg)

.jpg)

.jpg)

.jpg)

-(1).webp)

Social Media Link